Leveling with foam, also known as foam leveling or polyurethane foam injection, is a revolutionary technique used to raise and stabilize uneven concrete surfaces. Whether it’s a sunken driveway, patio, or foundation, foam leveling offers a cost-effective and efficient solution to restore the structural integrity and aesthetic appeal of various surfaces. In this extensive guide, we’ll delve into the world of leveling with foam, exploring the process, benefits, materials used, applications, and essential tips for mastering this innovative method.

1.1 What is Foam Leveling? Foam leveling is a non-invasive method that involves injecting high-density polyurethane foam beneath sunken concrete slabs. The expanding foam fills voids and raises the concrete, restoring its original level position.

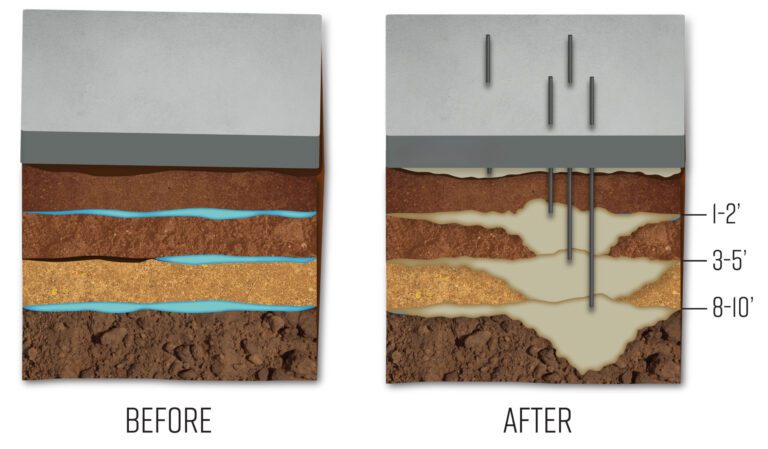

1.2 How Does Foam Leveling Work? A two-component polyurethane foam is mixed and injected through small holes drilled into the concrete. As the foam expands, it fills the voids, compacts the underlying soil, and lifts the concrete to the desired level.

2.1 Cost-Effectiveness: Compared to traditional concrete replacement, foam leveling is more cost-effective, as it requires less labor, time, and materials.

2.2 Speed and Efficiency: Foam leveling is a quick process, and the concrete is ready for use shortly after completion, minimizing downtime.

2.3 Minimal Disruption: Since only small holes are drilled into the concrete, there is minimal disruption to the surrounding area.

2.4 Environmentally Friendly: The polyurethane foam used in leveling is eco-friendly and does not harm the environment.

3.1 Residential Use: Foam leveling is ideal for repairing sunken concrete slabs in driveways, sidewalks, patios, and garage floors.

3.2 Commercial Use: Commercial applications include leveling concrete in warehouses, parking lots, loading docks, and industrial floors.

3.3 Infrastructure Repairs: Foam leveling can also be used to level concrete in bridge approaches, airport runways, and highway sections.

4.1 Site Evaluation: A professional assesses the site to determine the extent of the sunken concrete and the appropriate foam leveling solution.

4.2 Drilling Holes: Small holes are strategically drilled into the concrete surface, typically no larger than 5/8 inch in diameter.

4.3 Foam Injection: The polyurethane foam is injected into the holes, expanding and filling voids beneath the concrete.

4.4 Leveling: As the foam expands, it raises the concrete to the desired level, guided by the professional to achieve even results.

4.5 Patching Holes: After the leveling process, the holes are patched and color-matched to blend seamlessly with the concrete.

5.1 Work with Professionals: Always hire experienced professionals for foam leveling to ensure precise and effective results.

5.2 Address Underlying Issues: Identify and address any underlying soil or drainage issues to prevent future concrete settlement.

5.3 Regular Maintenance: Perform regular inspections and maintenance to address potential problems early on.

Foam leveling is a groundbreaking method that provides a cost-effective, efficient, and environmentally friendly solution for raising and stabilizing sunken concrete surfaces. Whether it’s for residential, commercial, or infrastructure repairs, leveling with foam offers an array of benefits, from minimal disruption and speedy completion to long-lasting results. By understanding the process, benefits, applications, and essential tips outlined in this extensive guide, you can master the art of foam leveling and ensure your concrete surfaces remain level, safe, and aesthetically pleasing for years to come.

Get the quality you deserve from Detroit Concrete Leveling. If you’re ready to start your project, contact us today for a free, no-obligation quote.